The digital twin developed in the preliminary project makes it possible to continuously record, merge and provide data on the course of production and the current condition of a concrete module. The focus here was on the lifecycle phases of planning, production and quality assurance as well as the transfer of the management shell concept from Industry 4.0 to processes in the construction industry. Here, the focus was on the description of individual, prefabricated concrete modules. In this project, it is no longer just the individual concrete module that is the subject of consideration, but the entire building structure. This includes the structure itself as well as all concrete modules belonging to the structure.

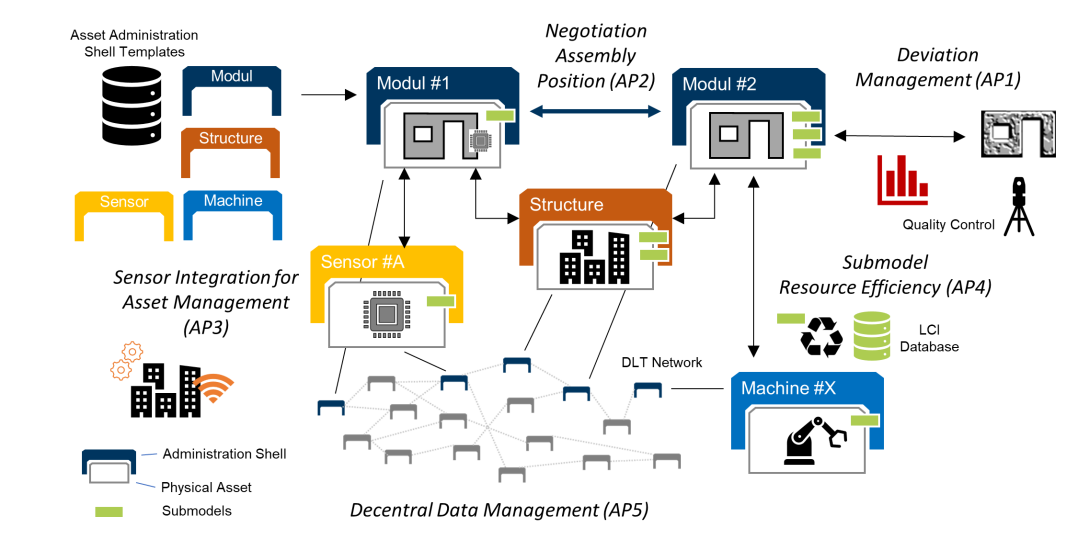

In particular, methods and concepts for lifecycle-based updating and interaction of digital twins for concrete modules are to be researched in this project. The results of the quality control are an essential basis for the decision whether a certain concrete module can be installed at the intended position. On this basis, concepts and methods are developed for the case that a concrete module does not meet the quality requirements and an adjustment of the processes is necessary. Embedding intelligent sensor technology in concrete modules offers enormous potential for digital transformation in the construction industry, right through to data-based business models. In order to enable sensor-based monitoring processes, e.g. of logistics, construction site assembly or damage monitoring in the use phase, a management shell-compliant data model is being created for the adaptive control of subsequent processes. The recording and evaluation of resource consumption and environmental impact throughout the entire life cycle is also becoming increasingly important. Therefore, the component-oriented collection of real data necessary for detailed LCA in addition to data from Lifecycle Inventory (LCI) databases will be explored as a hybrid approach to build a digital product memory based on the management shell. Structures are typically characterized by a very long useful life and the digital twins need to be continuously updated and made available. Therefore, a concept for decentralized data storage based on distributed ledger technology (DLT) is developed in order to provide the data required by different stakeholders at the required location at any time.

In summary, the project is divided into 5 work packages:

WP1: Management of production-related deviations.

AP2: Agent-based negotiation of assembly positions

AP3: Generic description of sensors in the concrete module and interaction concepts for the utilization phase

AP4: Recording of resource consumption

AP5: Concept for decentralized data management

Titel:

SPP2187 - Phase 2. Concepts for lifecycle-based updating and interaction of digital twins for prefabricated concrete modules.

Type:

Research groups

Project owner:

Deutsche Forschungsgemeinschaft (DFG)

Website:

https://www.ruhr-uni-bochum.de/spp2187/

Team:

Oliver Vogt M.Sc.

Project Partners:

TU Berlin

Ruhr-Universität Bochum

TU Chemnitz

TU Dresden

Leibniz Universität Hannover

Karlsruher Institut für Technologie

TU München

Universität Stuttgart