The availability of mechanized tunneling systems is strongly dependent on the design and performance of the support and maintenance processes. The aim of the subproject is therefore to analyze and control the tunneling processes. With the help of these simulation models, production-related assessments of the performance capabilities and sensitivities of important components of the entire tunneling system were carried out. In the first phase of the collaborative research center, production-related core processes and interdependencies of mechanized tunneling were first determined and classified. Disturbances and their dependencies were systematically classified and their influences and propagation effects were investigated on the basis of flexible simulation components. In the second phase of the subproject, the focus was on new concepts for optimized planning of maintenance intervals, taking into account failure scenarios and the wear of excavation tools. By developing simulation-based models, it was possible to investigate these influences in the holistic context of tunneling projects during the planning phase. The developed simulation model was verified and validated on the basis of a real project. The optimization framework created in the course of the second phase thus enables a construction-related evaluation of the robustness of maintenance strategies in mechanized tunneling, taking into account fluctuating input values as well as different project variants. In the third phase, concepts for incident management during excavation and for online optimization of production and logistics processes will be implemented on the basis of computational steering specific to tunnel construction. The focus of the project is on real-time analysis and forecasting of the production and logistics processes. For this purpose, the methods and simulation components of the first two phases are used and extended by components of real-time control and risk management.

Title:

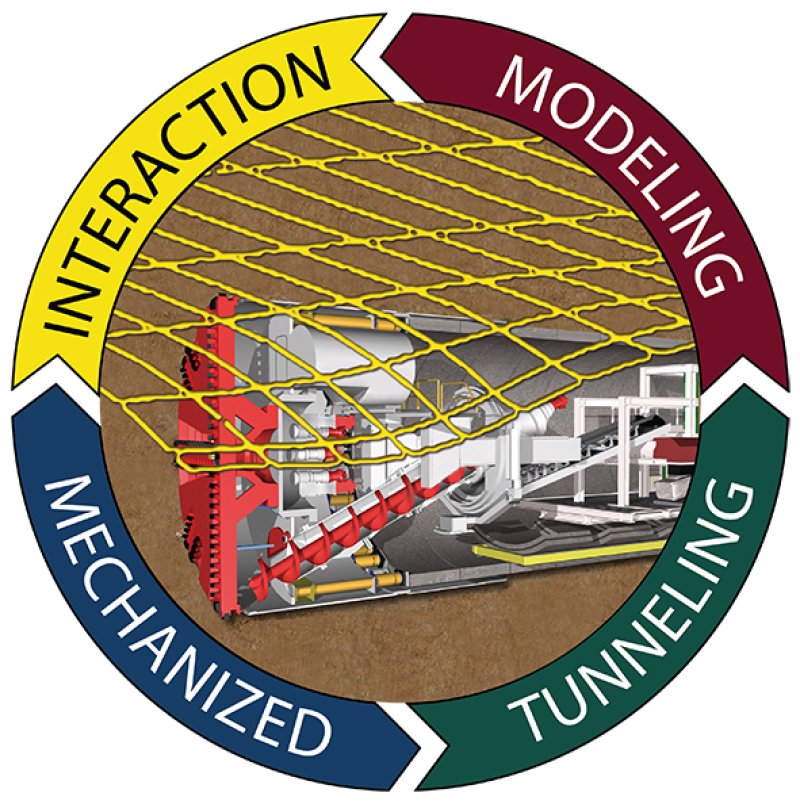

Interaction models for mechanized tunneling

Type:

DFG collaborative Research Center

Coordinators:

Team:

Contact:

Chair of Computing in Engineering

Prof. Dr.-Ing. Markus König

Bldg. IC, Room 6-59

Universitätsstraße 150

44780 Bochum