11.10.2021

Experts estimate that the global population will grow by two billion people in the next 30 years. As the population grows, so does the need for affordable housing. Concrete is already the most widely used building material and will play an important role in meeting the future demand for affordable housing, particularly due to its suitability for prefabrication.

The aim here must be to reduce material consumption through consistent prefabrication with quality assurance and to prevent production errors in order to ensure the fastest possible assembly on the construction site. An important factor here is the use of information and communication technologies (ICT) throughout the entire value creation process.

From September 15 to 17, the 13th European Conference on Product and Process Modeling (ECPPM) took place online rather than in Moscow as planned this year due to the pandemic. The biennial conference series provides a platform for researchers and scientists to present their latest research results in the fields of product and process modeling and information and communication technology for the construction industry. The focus is on the exchange on the development, standardization and industrial implementation of new BIM technologies.

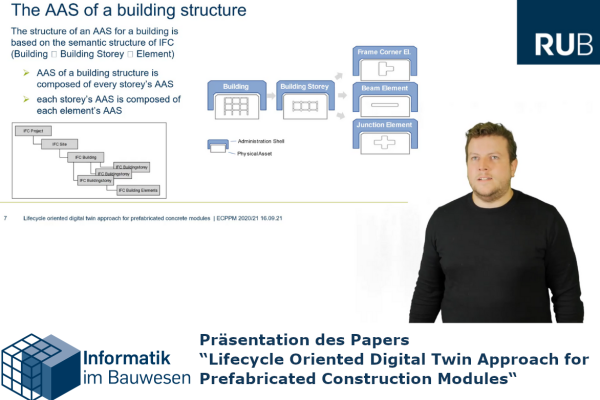

The paper "Lifecycle oriented digital twin approach for prefabricated concrete modules" by the authors: M. Wolf, O. Vogt, J. Huxoll, D. Gerhard, S. Kosse and M. König was presented online during this conference. To implement the concept of the digital twin, the aim is to develop data and interaction models from the manufacturing industry for industrialized, fault-tolerant rapid production of precast concrete parts. For efficient and precise production, all data relevant in the context of production must be continuously collected, combined and made available. This digital information enables individual production processes to be coordinated more precisely and ultimately increases the efficiency of production machines. The prerequisite for this is the digital twin as an integrated digital data model that combines current BIM concepts with established Industrie 4.0 methods for controlling all processes and interactions.

Experts estimate that the global population will grow by two billion people in the next 30 years. As the population grows, so does the need for affordable housing. Concrete is already the most widely used building material and will play an important role in meeting the future demand for affordable housing, particularly due to its suitability for prefabrication.

The aim here must be to reduce material consumption through consistent prefabrication with quality assurance and to prevent production errors in order to ensure the fastest possible assembly on the construction site. An important factor here is the use of information and communication technologies (ICT) throughout the entire value creation process.

From September 15 to 17, the 13th European Conference on Product and Process Modeling (ECPPM) took place online rather than in Moscow as planned this year due to the pandemic. The biennial conference series provides a platform for researchers and scientists to present their latest research results in the fields of product and process modeling and information and communication technology for the construction industry. The focus is on the exchange on the development, standardization and industrial implementation of new BIM technologies.

The paper "Lifecycle oriented digital twin approach for prefabricated concrete modules" by the authors: M. Wolf, O. Vogt, J. Huxoll, D. Gerhard, S. Kosse and M. König was presented online during this conference. To implement the concept of the digital twin, the aim is to develop data and interaction models from the manufacturing industry for industrialized, fault-tolerant rapid production of precast concrete parts. For efficient and precise production, all data relevant in the context of production must be continuously collected, combined and made available. This digital information enables individual production processes to be coordinated more precisely and ultimately increases the efficiency of production machines. The prerequisite for this is the digital twin as an integrated digital data model that combines current BIM concepts with established Industrie 4.0 methods for controlling all processes and interactions.